In 2001, Sino-Origin Mould changed its name to Sino Mould.

Sino people have always considered quality as a fatal factor for company’s survival and development. Since its establishment, Sino has started to formulate its own quality standard. On the basis of the European Standard known for high standard and restrict requirement, Sino has made a set of “Sino Mould Quality Standard” which is stricter. These standards are collected from successes and failures of large amount of practices, which are also closely integrated with reality. Today, Sino people attach great importance to quality, and take all the consideration for customers.

To improve the quality of products, Sino makes many efforts on production equipment improvement. In 2006, Sino Holdings invested USD 2.5 million in importing high precision equipments from Europe & Japan, such as: SODICK EDM, SODICK Wire Cutting, 6-meter CNC Milling Center, 320Ton Mould Pressing Machine, Gun Drilling Machine, and other precision equipments. These equipments ensure the first-class quality of Sino Mould.

Sino pays much attention to quality, and refined the quality from surface to point. To guarantee the quality, a quality management department was set up to control the process and assure the quality. Early in 2006, Sino process management department was established. Being responsible for mould production process scheduling and process management, it ensures the controllability of production process and the timeliness of delivery.

Sino Holdings has over 60 3D and 2D designers and engineers, who have excellent concept and rich experience in plastic, mould design and processing. Even for those experienced engineers, they also deal with every mould carefully, and take the responsibility to make the design better. We believe that the more time we spent on design, the less time we need in the production process.

Sino Holdings has a strong team for project research and development. Hereby over 10 top engineers work together to invent new mould structure design, new technology development and patent product invention. We continuously improve some kinds of products on structure and technology innovation, and we never stop pursuing better design. In recent years, Sino R&D Department has achieved 43 different types of new technology about mould structure design, machinery tooling, injection system solution, high-tech electronic products, etc.

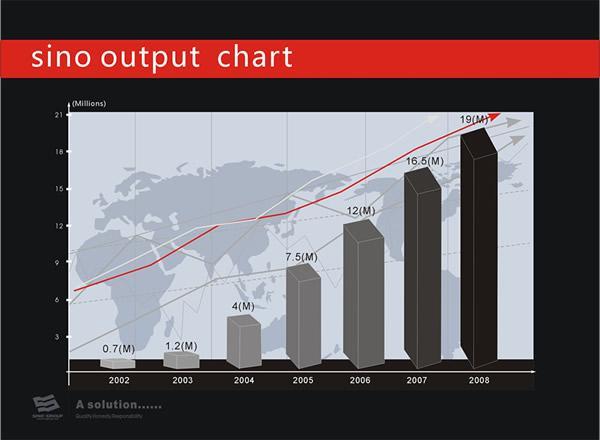

Thanks to this outstanding team, Sino Mould’s sales have been increasing year by year.

In 2002, annual sales revenue ---USD 0.7 million

In 2003, annual sales revenue---USD1.2 million

In 2004, annual sales revenue---USD 4 million

In 2005, annual sales revenue---USD7.5 million

In 2006, annual sales revenue---USD12 million

In 2007, annual sales revenue---USD16.5 million

In 2008, annual sales revenue---USD19 million

Sino takes the leading place in mould industry.

With several years’ development, Sino has developed from a single mould exporting enterprise to a new Holdings Group which is able to offer our customers a complete solution. In 2006, Sino has succeeded in providing our customers with fine solutions in many projects, such as High Speed & Thin Wall IML Solution, Gas Aided Injection Molding Solution, and Double Color Rotary Injection Solution, etc.

Presently, Sino Holdings consists of 7 branch companies: Sino Mould Co., Ltd., Sino Packaging Mould Co., Ltd., Sino Pipe Fitting Co., Ltd., Dakumar Machinery Co., Ltd., Anole Injection Moulding Technology & Service Co., Ltd., Sino Electronic Co., Ltd., and Sino Auto Mould Co., Ltd.

In 2008, the middle & senior manager conference was held. It reaffirmed the importance of quality, defined the focus of the work this year and ensured the direction of development in the future.

In the beginning of 2009, the members of Sino Holdings gathered again to discuss the plan for future development. The people from each branch company summarized the achievements and defects of the last year, and proposed a new development plan. They showed strong confidence in overcoming the bad impacts made by economic crisis.

Faced with the serious economic recession, Sino continuously keeps strong tendency towards further development.